____________________________________________________________________________________

TLE 4X FAB

_____________________________________________________________________________________

Innovation · Creation · Design · Fabrication

Straight axle conversions, complete engine

conversions, TIG welding, custom suspension design, custom roll cage

fabrication, gear setup

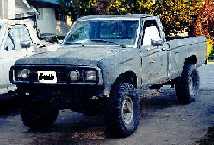

1987 Ford Ranger 2WD

The front suspension is able to articulate to these

extremes without the lower coil spring mounts separating from the front

axle. In other words, the front axle coil springs are not designed to

separate from the front axle for added droop. A “triangle” style front coil

spring system was designed. The engine and transmission was relocated to

the middle of the truck to accommodate the front suspension designs. Larger

picture here. A Ford Ranger, originally a 2 wheel drive pickup,

tackling the ramp. This truck is an example of what can be achieved through

“out of the box” innovation and design. As you can see from comparing the

location of the passenger front wheel to the driver front wheel, there is

over 5 feet of front suspension travel from full droop to full compression

This truck is also a daily driver and pretty good on gas thanks to the

Triton 4.6L V8. Click

here

for larger picture.

|

|

|

|

|

Bigger

Pic |

||

|

|

TLE 4x Fab Unit #1–33167 London Ave. Mission,

B.C., Canada, V2V 4P9 604.814.0094 tle4xfab@hotmail.com |

|

|

X |

||

|

|

|

|

|

Innovation · Creation · Design · Fabrication |

|

|

|

|

|

The ideal off-road vehicle has a low

Center of Gravity (CoG) and reasonable ground clearance. A low center of

gravity is needed to reduce the likelihood of tipping over on off camber

maneuvers. Ground clearance is needed to simply avoid getting stuck. Of

course, you can’t obtain one without sacrificing the other. That is, more

ground clearance = increased CoG and vise versa. The engine and transmission was

relocated the middle of the truck. The primary reason for relocating the

drivetrain is to make room in the engine compartment to accommodate a

long-travel front suspension design. There are several other inherent

benefits: 1. Better weight distribution, 2. Keeps the engine and transmission

out of trouble since it was mounted about 8” higher than it was in engine

compartment. 3. Serviceability is easier. There are two drivetrains ready for

this truck, a 4.6L Triton V8, and an old 460 BB. Engine swaps are extremely

easy – plenty of room and a wide open space. |

Unfortunately, relocating and

raising the engine and transmission means raising the Center of Gravity

(CoG). This is not good – especially for a vehicle designed to be a rock

crawler. So, to lower the CoG and obtain a

crawler gear ratio of thousands-to-one, a custom secondary drivetrain was

designed. The engine is mounted to the transmission which is mounted to the

transfer case, like any other 4x4. Lets call this the “primary drivetrain”.

Unlike other 4x4’s, the primary drivetrain is mounted in the middle of the

truck about 8” higher than normal. A driveshaft was fabricated to mate the

front output shaft of the primary drivetrain to the input shaft of the

secondary drivetrain which is divorce-mounted alongside the frame rail

(returning the CoG back to a favourable spot), The secondary drivetrain

thereby lowers the CoG and gives an overall crawl ratio of about 2650:1. The secondary drivetrain can be

considered one large divorced transfer case. It consists of two 4-speed

manual transmissions mounted front to back which is mounted to another

transfer case. This final transfer case powers the front and rear axles

through a custom fabricated driveshaft. Custom shift linkages have been

fabricated so all transmissions can be shifted from inside the truck. The secondary

drivetrain is mounted solidly into place near the right hand side frame rail.

It’s only link to the primary drivetrain is a single driveshaft. |